What should be paid attention to when using a bimetal thermometer?

- Share

- Issue Time

- Sep 8,2020

Summary

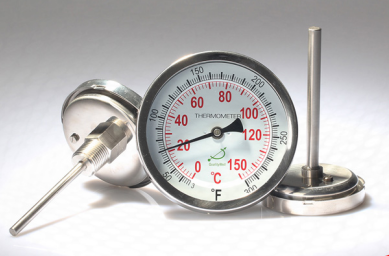

Bimetall thermometer is a kind of on-site measuring instrument for low and medium temperature.It can directly measure the temperature of liquid, steam and gas in the range of - 50 ℃ to + 500 ℃ in various production processes.It is widely used in industrial equipment. So what should be paid attention to when using a bimetal thermometer?

Bimetall thermometer is a kind of on-site measuring instrument for low and medium temperature.It can directly measure the temperature of liquid, steam and gas in the range of - 50 ℃ to + 500 ℃ in various production processes.It is widely used in industrial equipment. So what should be paid attention to when using a bimetal thermometer?

Based on the needs of the environment and the installation environment, we summarized the following five issues that should be paid attention to when using a bimetal thermometer:

1.The length of the bimetal thermometer protection tube immersed in the measured medium must be greater than the length of the temperature sensing element,Generally, the immersion length is greater than 40mm, and the immersion length of 0-50 ℃ range is greater than 50mm to ensure the accuracy of measurement.

2.All kinds of bimetal thermometers should not be used to measure the temperature of media in open containers,the live contact thermometer should not be used in the control circuit where the working vibration is large.

3.In the storage, installation and transportation of bimetal thermometers, it is necessary to avoid collision with the protective tube, and do not bend the protective tube and use the meter as a wrench.

4.Thermometers should be inspected regularly in normal use.Generally, every six months is appropriate. Electric contact thermometer is not allowed to work under strong vibration, so as not to affect the reliability of the contact.

5.The operating temperature of the instrument should be 1 / 3 ~ 2 / 3 of the scale range.